|

2. Vibration

isolation table: 1 set

|

Qty

|

Spec

|

|

2.1

Tabletop

specifications

|

1

|

Length:

1.2m

Width: 0.9m

Thickness: 15cm

Table top

is magnetic stainless steel 10mm,

bottom is 5mm.

Top plate is brush finished.

Core: high density plated steel

honeycomb

Mounting hole pattern: M6 holes

with 25mm center to center

spacing.

Edge to first hole center =

25mm

Maximum screw length =

8mm

Weight =

200kg

Table top is suitable to clean

room.

We

recommend our cast iron table

top,

Weight of the table is twice

heavy in comparison with

honeycomb.

|

|

2.2 Table

legs

|

Set of

four

|

Self

leveling vibration isolators

Compatible with the tabletop of

size as specified in 1.1.

Resonant frequency: Vertical =

1.5Hz

Transmissibility:

20Db at 10Hz

Isolation

type: Air isolator

Local capacity (set of 4):

500kg

Height of table top from the

floor including table leg:

0.75m

Finish: Black

|

|

2.3 Air

compressor with air filter

|

1

|

Max Air

pressure: 100psi

Tank size: 26 liters

Power: 220V AC/50 Hz

Noise level: 47dB (outer package

direct)

Weight = 20kg

Air filter/regulator:

|

a)

filter for 5 micro

particles

b) filter moisture

c) Outlet air pressure =

100psi

|

|

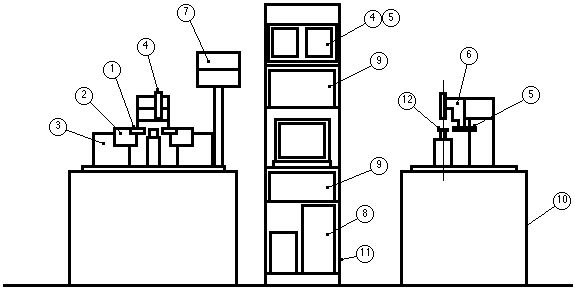

3. Device stage

(central stage)

|

3.1 Device

stage

|

1 set

|

Stand

material: invar

Device holder:

detachable

Device

holder is for only each size and

each face angle.

One holder

do not suit every

devices.

|

4. Fiber and

waveguide grippers

|

4.1 Fiber

gripper

|

1 set

(2 BFH & 2 FAG)

|

Tweezer:

motorized control

Tweezer

suits for each size of fiber or

fiber array.

So one tweezer does not suit for

every fiber or every

arrays.

|

|

4.2 Integrated optic waveguide device grippeZ

|

1 set

(size 1 & 2 both)

|

Vacuum

hold

Device

gripper suits for only one size

device.

So one gripper does not grip all

size of device.

|

5. Control unit

(hardware and software)

|

5.1 Stage

controller

|

1

set

|

Power

supply: 240V, AC50Hz

Interface:

GPIB

|

|

5.2 Control

PC (Do not quote for custom made

PC)

|

One

|

Operating

system: Windows 2000

CPU: Intel Pentium IV processor

of higher

Hard disk: 40GB

Memory >256MB

Floppy drive: 3.5''

CD-ROM & CD writer:

40X

|

|

5.3

Additional hardware/

accessories

|

1 set

|

AD

board

I/O board

MCB board

VIDEO board

|

|

5.4

Software

|

1No

|

1.

Auto-alignment

|

a)

Auto align through

b) Auto align step

motion

c) Image processing

method for rough

alignment of device core

and fiber core.

d) Fully automated UV

dispenser and UV

lamp.

|

2. Manual

alignment

12 axes can be control by desired

step.

Near filed pattern

|

6. Light source

(infrared and visible): 1 set

|

6.1

Infrared

|

2

Nos

|

Agilent

81657A

Wavelength:

1310/1550nm

Output power = 2mW

State of polarization: polarized

TE/TM

Optical connector: FC/PC

Power supply: 240V AC50Hz

Interface: GPIB

|

|

6.2

Visible

|

1No

|

Wavelength

= 635nm

Output power: 5mW

Stabilized O/P power <

+/-4%

Optical connector: FC/PC

Power supply: 240V AC/50 Hz

ESD protected

|

7. Detector

(infrared and visible): 1 set

|

7.1

Infrared

|

2 Nos

|

Agilent

81634A

Wavelength range: 800 -

1700nm

Sensitivity: -80dBm to +10dBm

Power resolution: 0.001dB

Power and wavelength display:

LCD

Power supply: 240V AC/50 Hz

Interface: GPIB

Connector: FC/PC

|

|

7.2

Visible

|

2 Nos

|

Anritsu

ML9001A, MA9411A

Responsibility: 100ms

Wavelength range: 380 to

1150nm

Sensitivity: -70dBm to +10dBm

Detector area diameter = 5mm

Power resolution: 0.001dB

Power and wavelength display:

LCD

Power supply: 240V AC/50 Hz

Interface: GPIB

Connector: FC/PC

|

8. UV light source

with guide: 1 set

|

8.1 Light

source

|

1

set

|

Lamp

intensity=200W

Lamp intensity = 150W

Shutter

control: programmable exposure

control

Hour meter:

standard

|

|

8.2 Light

guide

|

1

set

|

D=3.5mm

Length: 0.5m

Flexible UV lightguide with two

branch

UV bundle

dia = 3.5mm

|

9. Protective

goggles (UV & IR)

|

9.1

Protective goggles

|

1 set

(2 UV +2 IR)

|

|

a)

UV light

|

|

Optical

density = 9

Visible light

transmission = 45%

|

|

b)

IR laser

|

|

density

= 4

Visible light

transmission =

80%

|

|

10. Epoxy

dispenser

|

10.1

Dispenser

|

1 set

|

Dispensing

pressure: 0 to 100PSI

Dispensing duration: 1m sec to 10

sec

Pneumatic

supply source:

Compressor

Power

supply: 220V AC, 50 Hz

|

11. CCD camera and

monitor (to view X axis)

|

11.1

Camera

|

1No

|

Number of

effective pixel = 768 x

494

S/N =

50dB

Fixed focus

objective lens: 0.5X, 4X,

8X

Working

distance = 40mm fix

Lamp: our

special LED light

|

|

11.2

Monitor

|

1No

|

Color

monitor

Size: 12 inch

|

12. CCD camera and

monitor (to view Y axis)

|

12.1

Camera

|

1No

|

Number of

effective pixel = 768 x

494

S/N =

50dB

Fixed focus

objective lens: 0.5X, 4X,

8X

Working

distance = 40mm fix

Lamp: our

special LED light

|

|

12.2

Monitor

|

1No

|

Color

monitor

Size: 12 inch

|

13. IR camera and

monitor (to view Z axis)

|

13.1 IR

Camera

|

1No

|

Response

range: 800 to 1700nm

Resolution: 450 TV

lines

|

|

13.2

Monitor

|

1No

|

Color

monitor, size = 12

inch

|

14. Travel stage for

camera, dispenser and UV light guide: 1

set

|

14.1 Long

travel stage

|

1No

|

Linear DC

servo

Z-axis:

+/-250mm

Resolution(Z)

= 1 micron

|

|

14.2 Stage

for UV dispenser

|

1No

|

Pulse motor

drive

X-axis:

+/-25mm

Y-axis: +/-50mm

Resolution: 1 micron

Fully covered for guard from UV

light

|

|

14.3 Clamp

for UV light guide

|

1No

|

Flexible

mechanical cramp

|

|

14.4 Stage

for visible CCD camera (view Y

axis)

|

1No

|

Pulse motor

drive

X-axis:

+/-25mm

Y-axis: +/-50mm

Resolution:

1 micron

|

|

14.5 Stage

for visible CCD camera (view X

axis)

|

1No

|

Pulse motor

drive

X-axis:

+/-50mm

Y-axis: +/-50mm

Z-axis: +/-12.5mm

Resolution:

1 micron

|

|

14.6 Stage

for IR camera (view Z

axis)

|

1No

|

Pulse motor

drive

X-axis:

+/-25mm

Y-axis: +/-50mm

Resolution:

1 micron

|

|

14.7

Controller

|

1No

|

Auto and

manual

|

15.1 Instrument

rack

|

15.1

Instrument rack

|

1No

|

Approximate

size: 2.5 x 2 x 6 ft

Support:

casters

Color: cream

Door: front open, back

open

|

16. Environmental

conditions:

The bidder is

advised to make sure that all the

subsystems/components work satisfactorily

under these room conditions. The bidder

will specify the system operating and

storage room conditions.

|

16.1

Room

|

|

Clean

room

|

|

16.2

Temperature

|

|

18 to 23

C

|

|

16.3

Humidity

|

|

Maximum

75%

|

|

Optional

Optional